- Whatsapp: +8618167388897

- Email: [email protected]

Product Information:

Flanged valves are a crucial component in various industrial applications, designed to control the flow of liquids, gases, or slurries through piping systems. These valves are equipped with flanges on either end, which allow for easy installation and removal by bolting them to the corresponding pipe flanges. Flanged valves are available in a range of types, including gate valves, globe valves, ball valves, and butterfly valves, each suited for specific functions. They are commonly used in industries such as oil and gas, chemical processing, water treatment, and power generation, where secure and reliable connections are essential.

1, Superior Durability: Robust construction allows flanged valves to withstand high pressures and temperatures, ensuring long-lasting performance.

2, Leak-Proof Seal: Flanged connections provide a tight, secure seal, minimizing the risk of leaks and maintaining system integrity.

3, Easy Installation and Maintenance: The flanged design simplifies installation and removal, reducing downtime and maintenance costs.

4, Versatility: Compatible with various piping systems, flanged valves can be used across multiple industries, enhancing their adaptability.

5, Cost-Effective: The combination of durability, easy maintenance, and reliability makes flanged valves a cost-efficient choice for industrial applications.

| Item | Our Offer |

| MOQ | 200pcs |

| Sample#2 | Free sample can be provided for bulk order |

| Lesading Times | Sample:5-10days ;Bulk Order:30-60 working days,depending the qtys |

| Main Product | Gate Valve, Globle Valve,Check Valve ,Y Type Strainer,Ball Valve Wafer Type Check Valve,Solenoids Valve,Stainless Steel Pipe Fittings |

| Customize LOGO | HuanYi |

Producing Department

Warehouse

Packaging Workshop

The main role of stainless steel valves in industry includes controlling the flow of fluids, ensuring the safe operation of the system, and improving the efficiency and reliability of the system. Valve control can use a variety of transmission methods, such as manual, electric, hydraulic, pneumatic, etc., to achieve pressure, temperature or Other forms of sensing signals under the action of the predetermined requirements, or do not rely on sensing signals for simple open or close. Valves rely on the drive or automatic mechanism to make the opening and closing parts for lifting, sliding, rotary swing or rotary movement, thereby changing the size of its flow area to achieve its control function.

Stainless steel threaded gate valves are a type of valve characterised by a body with internal or external threads, allowing a threaded connection to the pipeline. This type of valve is usually used in normal low-pressure projects, and if it needs to be used in high-pressure valves, it is not suitable for threaded connections, and should be selected as a welded or flanged valve. Stainless steel threaded gate valve gate with the stem together for linear movement, this direction of movement perpendicular to the direction of the fluid, so that the gate valve can only be fully open or fully closed, can not be regulated or throttled. Stainless steel gate valve materials include 304 stainless steel, 316 stainless steel, 321 stainless steel, etc. These materials have good corrosion resistance and mechanical properties, suitable for a variety of media, such as water, oil, vapour, steam, and other media. Such as water, oil, steam, acid, alkali, ammonia, urea and natural gas containing sulfur. Stainless steel threaded gate valve has a wide range of applications, including petroleum, chemical, hydro, thermal power station and other systems on the pipeline, used to cut off or connect the pipeline medium. In addition, the gate plate of stainless steel gate valve can be designed as rigid or elastic to adapt to different working conditions and media characteristics. Rigid gate overall no deformation, while the elastic gate can produce a small amount of deformation to improve manufacturability and make up for the angle of the sealing surface in the process of processing deviation.

Stainless steel threaded globe valve is a kind of valve, which is characterised by the upper sealing seat designed on the bonnet, which makes the packing seal more reliable in the fully open state and facilitates the replacement of the packing. This valve is suitable for a variety of working conditions on the pipeline, used to cut off or connect the pipeline medium, such as petroleum, chemical, metallurgy, electric power, Paper, pharmaceutical, food, water treatment and other industries. Advantages of stainless steel threaded globe valve include its stem threads on the outside of the valve body, which makes the valve stem is not eroded by the medium, easy to lubricate, so this structure is more commonly used. In addition, the opening height of the stainless steel threaded globe valve is 25% ~ 30% of the nominal diameter, the flow rate has reached the maximum, indicating that the valve has reached the fully open position, which indicates that its design and manufacturing standards follow the Specific norms to ensure its performance and safety

Stainless steel horizontal check valve is a kind of valve used in piping system, its main role is to prevent the medium backflow. This valve relies on the force generated by the flow of the medium itself to automatically open and close, belonging to a kind of automatic valve. Check valves have a wide range of applications, including but not limited to petroleum, chemical, thermal power station and other working conditions on the pipeline. Stainless steel horizontal check valve material usually includes carbon steel, stainless steel, etc., can adapt to different working pressures and temperatures, to ensure the safe and stable operation of the pipeline system!

Stainless steel vertical check valve is a kind of valve that can prevent the backflow of the medium, also known as check valve, check valve, backflow valve or backpressure valve. Its main role is to ensure that the medium can only flow in one direction when the medium flow direction changes or pressure changes, thus preventing the medium from flowing backwards. This type of valve is widely used in various industrial fields, including chemical, petrochemical, petroleum, paper, mining, electric power, liquefied gas, food, pharmaceutical, water supply and drainage, municipal, mechanical equipment supporting, electronic industry, urban construction and other fields. Stainless steel vertical check valve design and material selection to make it can adapt to high pressure and high temperature working environment, to ensure the safety and stable operation of the system.

Stainless steel threaded Y Type Strainer is a small device used to filter a small amount of solid particles in the liquid, designed to protect the normal operation of the equipment. This kind of filter is usually installed at the inlet end of the piping system that conveys the medium, such as the inlet end of the pressure reducing valve, pressure relief valve, water level setting valve or other equipments, which is used to remove impurities in the medium To protect the normal use of valves and equipment. Y filter has the characteristics of advanced structure, small resistance, convenient drainage, etc. It is suitable for water, oil, gas and other media. The mesh size of the filter mesh varies according to the type of media, the water mesh is generally 18-30 mesh, the gas mesh is 10-100 mesh, and the oil mesh is 100-480 mesh. Stainless steel threaded Y-type filter consists of a receiver, a main pipe, a filter blue, a flange, a flange cover and fasteners, etc. When the liquid enters the filter blue through the main pipe, the When the liquid enters the filter blue through the main pipe, the solid impurity particles are blocked in the filter blue, while the clean fluid passes through the filter blue and is discharged from the filter outlet. This kind of filter is widely used in metallurgy, chemical industry, petroleum, papermaking, medicine, food, mining, Electric power, urban water supply and family and other fields, is an indispensable device on the pipeline for conveying media.

Stainless steel one-piece ball valve is a kind of valve, which is characterised by compact structure, small volume, light weight, with the advantages of low fluid resistance, easy operation, simple maintenance and so on. This valve is mainly used to cut off or connect the medium in the pipeline, can also be used for fluid regulation and control, especially suitable for pipeline systems containing fibres, tiny solid particles and other media. Stainless steel one-piece ball valve body material is usually 304 (CF8) or 316 (CF8M) stainless steel, has good corrosion resistance, and is Applicable to a variety of working environments. Its engineering diameter range from 1/4 “to 4” (DN6 ~ DN100), engineering pressure up to 1.6 ~ 6.4MPa. A piece of ball valve sealing performance is excellent, large flow capacity, flow resistance coefficient is small, long service life, usually used in sealing requirements of strict occasions, such as control of gases, Liquid, steam media, but also suitable for controlling sewage and media containing fibrous impurities.

Stainless steel two-piece ball valve is a commonly used equipment for fluid control, consisting of two parts, namely, the left and right two-piece valve body is composed of bolted together.

This kind of ball valve is fixed by two pieces of valve body clamping the ball valve, maintenance is relatively difficult, the key lies in the middle of the screw tightness, which is directly related to whether the seal is tight or not. Stainless steel two-piece ball valves are mainly used in atmospheric pressure and high pressure environment, especially in the non-standard category of nominal diameter below DN50, belongs to the application of two-piece valves. In addition, the design features of this type of ball valve include wedge sealing structure and self-cleaning structure of the sealing surface, which ensures that the valve can guarantee reliable sealing performance under various working conditions.

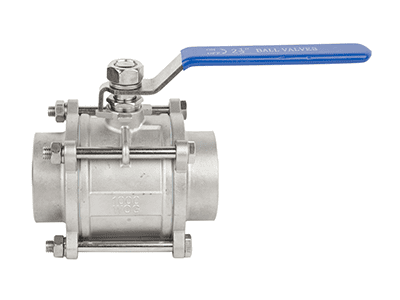

Stainless steel three-piece ball valve is a kind of ball valve made of stainless steel 304 or 316. The internal threaded connection of this type of ball valve is a two-piece connection structure

with full bore diameter, and the connection methods include G thread, NPT thread, PT thread, etc.. Stainless steel three-piece ball valves have a nominal pressure range of 1.6-6.4MPa, a wide range of applicable temperatures, from -20℃ to 232℃ to 350℃, and are suitable for water, oil, gas and certain corrosive liquids and other media. This valve is widely used in various industries because of its compact structure, easy operation and maintenance, reliable sealing and other characteristics1.

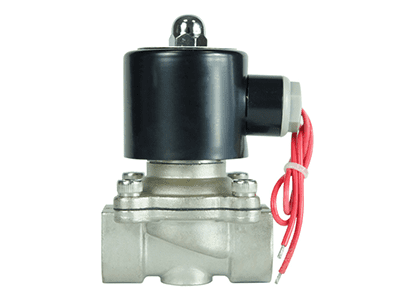

Stainless steel solenoid valve is a kind of industrial equipment, belongs to the automation basic components, used to control the direction of the fluid. It is an actuator, usually used in mechanical control and industrial valves above, the direction of the medium to control, so as to achieve the control of the valve switch. Stainless steel solenoid valve is often connected with the air filter and the return letter, forming a pneumatic triplex. This kind of solenoid valve has excellent corrosion resistance and sealing performance due to its material of stainless steel, which is suitable for a variety of media, such as corrosive liquids, ultra-clean liquids and edible liquids. Stainless steel solenoid valve is widely used in textile, printing, chemical, plastic, rubber, pharmaceutical, food, Building materials, machinery, electrical appliances, surface treatment and other production and scientific research departments, as well as bathrooms, canteens, air conditioning and other people’s daily life facilities. Its power supply includes 220V, 24V, 380V and other voltage levels, with zero pressure can also open the main valve, low differential flow, wide range of application, etc. Features. Stainless steel solenoid valve bonnet is threaded, easy to disassemble and maintain, made of special stainless steel, suitable for edible fluids, ultra-clean fluids and corrosive media. Stainless steel solenoid valve In addition, different use of media using targeted seals to further improve the rationality of the solenoid valve. Liquids, gases, oils can be mixed, special occasions can be continuously energised for a long time, the medium fluid temperature up to 220 ℃. Spool seal wear can be automatically compensated to improve the life and reliability of the solenoid valve

Stainless steel butt check valve is a kind of valve relying on the flow of the medium itself and automatically open and close the valve, mainly used to prevent the medium backflow. This valve is also known as the check valve, check valve, backflow valve or backpressure valve, belongs to a kind of automatic valve. Its main role is to prevent the media backflow, prevent the pump and drive motor reversal, as well as container media discharge. Stainless steel butt check valve is suitable for a variety of media, such as water, steam, oil, nitric acid, acetic acid, oxidising media, Urea, etc., with small size, light weight, compact structure, easy maintenance and so on. The valve plate adopts dyadic type, which can be closed quickly by itself under the elastic force of spring, so it has the function of preventing the medium from flowing backward. In addition, due to its quick-closing effect, it can be applied to horizontal or vertical installation, and the length of the valve body structure is small in size, good rigidity, safety and convenience.

Stainless steel pipe fittings are stainless steel pipe fittings used to connect or control the flow of fluids, such as tees, elbows, flanges, internal filaments, external filaments, and live joints. These fittings are used in industrial transmission pipelines as well as mechanical structural components in petroleum, chemical, medical, food, light industry, machinery and instrumentation, etc., in order To ensure the smooth transmission of fluids and the safe operation of the system. Stainless steel fittings play an important role in various industrial applications due to their corrosion resistance and lightweight properties.

These fittings are not only used to ensure the smooth transmission of fluids, but also largely affect the safety and reliability of the entire system. Therefore, choosing the right pipe fitting material and design is crucial to ensure the long-term stable operation of the system. Stainless steel is one of the ideal materials for manufacturing fittings due to its excellent corrosion resistance and lightweight properties.

Privacy Policy | SiteMap

Copyright Wenzhou Huanyi valve fittings Co., LTD